|

Brakedrum Generator

Not only will we use these generators on bicycles in the shelter but later we plan to use 8 of them for wind power and 2 for water power generation. We can't use wind and water power at the moment because the government won't allow us to. They say that wind power makes noise (I never got the chance to find out) and disturbs the neighbors and that water power would disturb the fish (Hah! They have killed most of them with winter salt from the highway, and agricultural sprays from the farms - long ago.) What is described here are generators made by taking the brakedrums off of old either F-250 or F-350 Ford pickups or vans. Some others may work but these were for what we had plans. The brakedrums were used simply for outer casings to hold the magnets and to provide the bearings to revolve them around the stator. Other designs can be made out brake disks or out of wood. The latter may be a lot more simple - although not as durable.

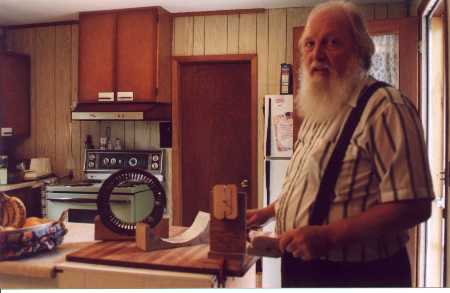

The post nuclear salvaging key to making these will be finding the stators and magnets. One will also have to find wire for the coils. My son and I were able to go to a metal scrap yard that literally had a mountain (about 20 feet high and fifty feet in diameter) of old motors. It was a hot summer day and we spent five hours going through the motors looking for ones with the right size stator. Once we learned what we were looking for we should have spent more hours or a couple of more days getting the right ones instead of, because of the heat, taking what we did and then later putting so much effort into making them fit. Below is a picture of a stator (on the left) and a brakedrum (on the right).The stataor is what you have to dig out of the old motor casings. The difficulty is finding a stator the right diameter to fit into the brakedrum or other housing that you are building. When you first get the stator it has copper wire all wrapped around it and through all those slots. You have to cut the wire (probably with a chisel although we used a cutting wheel) and then knock it out of the slots. The latter can be quite a task.

We were able to buy new magnets but new magnets will probably be hard to find after a nuclear war. We talked with many experts about this with the thought of making magnets. One idea that was suggested was crushing old magnets and then reforming the powder to the size that we need and then remagnetizing them. The best idea that we have at the moment is to simply take magnets out of old speakers and cut them into smaller workable squares or shapes and then assemble these into the shape needed. The magnet parts will adhere to each other and one could use some additional glue if they wanted to.

The basic concept is that the magnets are mounted around the inside of the brakedrum. In fact, glued in place there. The stator is then mounted inside the brakedrum and held stationary so that the brakedrum and magnets revolve around the stator when the brakedrum is turned by the bicycle, windmill blades or a waterwheel. The big problem is getting the stator with its coils mounted on the outside of it to fit inside the brakedrum with the magnets mounted in a circle around it on the inside of the brakedrum. One needs a small gap (the smaller the better) - but there needs to be some gap so that if there is wobble or anything the coil wires won't rub against the magnets and wear off the insulation from the coil wire. All the details for coil winding are available on this website and you will find them, for example, in the .pdf file dealing with wooden generators. The details for the coils remain the same so rather than being redundant I am not covering them here.

There are two versions of brakedrum specifications. One comes from the UK and the other from the US (actually I got them from Bob Budd in Canada).

Here are some basic dimensions for the two versions.

Other arts involved are those of making propeller blades and vanes for wind generators and water driven devices of some sort for those that are used with waterpower. These are separate issues that I cover on their individual specific pages. Rather than each individual trying to build their own - I would recommend that a group of skilled mechanics specialize in the art. In fact in a shop they could create sub-specialties. Coil winding and magnet assembly being but two examples. I would not call learning to build these devices trivial. All the information is here but people many times asked me why we didn't just go out and buy one - because it would have been many times cheaper. However, our purpose was to learn this technology so that we could communicate it to others in a time when they will have to build their own. Those inclined to study the art ahead of time will do well to visit brakedrum Details: Hugh Piggott's Website or brakedrum Details: Bob Budd's Website Hugh and Bob are the main designers of these brakedrum systems and you can get details from them on how to do it. Bob puts out an excellent video that I have bought and watched dozens of times. It would be a great thing to have.

|