|

Wood Butter

Churns Page 1 - Swinging, Revolving & Rocking Churns

The butter churns on this page all rely on the

motion of the cream container to churn the butter. There are no

paddles or dashers inside the cream container to agitate the

cream. Rather the cream box is swung, rotated or rocked to get the

cream moving inside the churn. The motion of the cream hitting

the ends of the container is what causes the butter to churn.

Revolving butter churns were especially popular with larger

creameries. These churns were very easily made in large sizes

since there were no paddles to deal with, they were very easily adapted

to mechanical power with a simple pulley and they were very efficient in

churning the cream. Click here for a picture of a 500 gallon revolving

box churn. This churn was called The Key City King and was

manufactured by N. S. Andrews of Dubuque, Iowa. This churn was

advertised in an 1893 dairy publication and was typical of the large

size revolving churns used at that time.

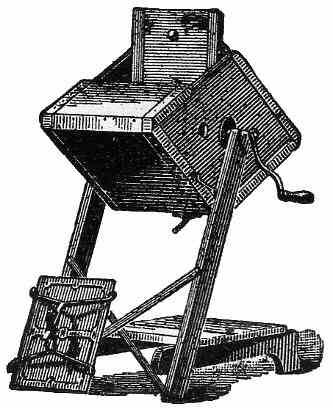

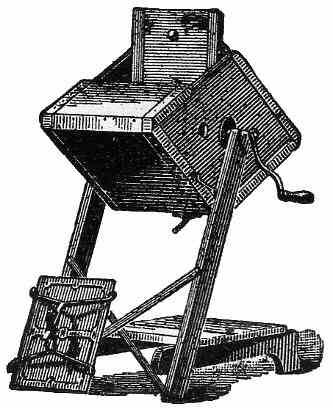

This is a Davis Swing Churn, although some very early literature

referred to it as a Davis Oscillating Churn. It was patented

on May 1, 1877 and September 9, 1879. The 1877 patent was granted

to Oliver Davis of Waterbury, Vermont and described a churn of similar

shape but it pivoted from below and was rocked back and forth by spiral

springs. The 1879 patent was granted to Francis Butler of Bellows

Falls, Vermont and assigned to the Vermont Farm Machine Company.

Butler was the secretary of the Vermont Farm Machine

Company. His patent described a churn almost identical

to the one pictured, which was suspended from above in a wood

frame.

These churns were made by the Vermont Farm Machine Company of Bellows

Falls, Vermont. This is a size 2 or 10 gallon capacity designed to

churn 5 gallons of cream. This size butter churn was listed at

$8.00 in an 1889 catalog from the company. They were still sold in

1913 and the price had increased by one dollar. This churn has

the plain frame. There was a folding frame available for a dollar

more. The folding frame made it easier to tilt the churn box to

drain out the buttermilk or wash water.

There were no paddles inside the churn. As the churn box

rocked on the cradle the cream rolled over on itself to make

butter. The company said this gentle action did not injure the

butter.

These butter churns were available in twelve sizes (7, 10, 16, 24, 30,

40, 60, 80, 100, 150, 200 and 300 gallons).

The largest sizes were designed to be suspended from the

ceiling beams of the creamery (picture).

For an additional 16 dollars this company sold a treadmill attachment

that allowed a dog, goat or sheep to supply the power to swing the churn

(picture).

This butter churn was awarded medals at the New Jersey State Fair, the

New England Fair, the International Dairy Fair, the Western New York

Fair, the Pennsylvania State Fair, the Carolina Fair, the Massachusetts

Mechanics Association and the Virginia State A & M Society.

This is a Creamery

Foot Power Churn. The handle allows one to use their foot as well

as their hand to swing the churn. It is stenciled as a No. 1 or 10

gallon small family size with the capacity to churn 1 to 4

gallons. It was manufactured in Louisville, Kentucky

by Creamery Churn Manufacturers. The butter churn pictured

above was patented by William H. Curtice of Eminence, Kentucky on

December 26, 1893 and January 15, 1895. The 1893 patent shows an

early version of the foot lever. The 1895 patent details the

foot lever as it appears on this butter churn as well as drawings for a

screen or strainer to insert in the body of the churn to

separate the butter and buttermilk when the churn is drained.

Thanks Dennis for letting us picture your churn.

This company

also sold a swing churn without the foot power called the Creamery Swing

Churn. It had upright handles on each end of the churn box so one

could swing it by hand. The Creamery Swing Churn was advertised

in 10, 15 and 20 gallon sizes. It also was patented by William

Curtice along with his brother Jesse on September 8, 1891.

Actually the

Creamery Swing Churn was first manufactured by J. F. Hillerich and

Son of Louisville, Kentucky. They called it the Dairy Swing

Churn (picture) and also

manufactured it under the Curtice patent of 1891. J. F. Hillerich

and Son would become famous as the manufacturer of Louisville Slugger

baseball bats. Switching from butter churns to baseball bats

turned out to be a great business decision. Thanks Dave and Myra

for the picture of your churn.

Some of William Curtice's early

patents were his most unique butter churns. On August 28, 1888 he

patented a butter churn that was powered by foot pedals similar to a

sewing machine (picture). The

operator sat facing the churn. This churn had a large,

ball shaped counter weight that hung below the churn on a rod to keep

the churn swinging once the motion was started.

This is a Star barrel churn. The oak

barrel was just tumbled end over end until butter formed.

There were no paddles inside the barrel but since the barrel was

only filled half full the cream would churn as it fell inside the

barrel. The barrel was rotated between 40-80 revolutions per

minute depending on size. Smaller churns would

be rotated between 60 to 80 revolutions/minute and as the

churns got larger the revolutions/minute could be decreased,

approaching the 40 revolutions/minute on the largest sizes. It was

important not to over crank a barrel churn. The cream needed to

fall from one end of the barrel to the other as it rotated. If the

barrel was cranked so fast that centrifugal force held the cream

at the end of the barrel the butter would not form. One

disadvantage of any churn that revolved was that it needed to be

sealed tight so it would not leak. The lid had to fit tight and

the churn could not be vented. If pressure built up during the

churning process the churn needed to be stopped and the pressure

relieved.

The barrel churn pictured above is a size 0 which was 5 (later called 6)

gallons and the smallest size. It sold for $2.85 in the 1896

Sears and Roebuck catalog, decreased to as low as $2.35 in

1912 and went back up to between five and six

dollars in the 1920's and 30's. Star barrel churns

were still available in

the 1942-43 Sears, Roebuck and Company catalog but

the price jumped to $7.19. They did not appear in the 1945-46

Sears catalog. The Montgomery Ward

catalog listed their brand of barrel churns in this size

for $3.00 in 1894-95, $5.00 in 1922, $5.95 in 1935-36 and $6.25 in

1940-41. The fact that this style of butter churn was sold for

over 50 years tells one how popular they were. These butter

churns were also available from Sears in 9 (later called 10), 15, 20, 25

and 35 gallon sizes although by the 1920's the two larger sizes were no

longer sold in the hand crank version. Sizes 15 gallons and

above could be ordered with a pulley to be driven by an external motor,

engine or treadmill. For many years Sears referred to their power

driven churns by the name "Success".

The earliest Sears barrel churns had a star symbol stenciled on the

barrel and in the mid 1920's the butter churns had the word

"Star" like the butter churn pictured above. The 1927 Sears

catalog referred to the factory being in northern Illinois. We

suspect that the Star barrel churns were made for Sears by J. McDermaid

of Rockford, Illinois. We have seen a J. McDermaid counter weight

that refers to the Star churn. In addition, John McDermaid was

granted at least three patents for a lever system to seal the lid of a

barrel butter churn that was identical to the lid used on the Star

butter churns. The dates of these patents were October 9, 1888,

March 19, 1889 and September 8, 1891.

J. McDermaid manufactured four barrel butter churns under his

own name, the Boss, the Favorite, the Columbian and the Belle Churn

(picture). John

McDermaid was granted one of the first barrel churn patents on October

24, 1876. This original patent described a barrel churn that had

beaters inside of the barrel to help break the cream and separate the

butter from the milk. These beaters were soon determined to be

unnecessary. Although this 1876 patent was not assigned in the

original patent papers, at some point John McDermaid must have granted a

half interest to H. H. Palmer and Company, which would become a

major competitor. We have also seen an advertisement from the

Aquatic Cream Separator Company of Rochester, New York for a Eureka

Churn which listed all the McDermaid patent dates. J. McDermaid

most likely manufactured this barrel churn also.

In addition to the J. McDermaid patents, there were many other barrel

churn patents. The majority of these concerned the closure or

sealing of the lid. One of the most prolific patent holders was H.

H. Palmer and Company of Rockford, Illinois. They manufactured

two popular barrel churns; the Acme Bail Churn and the

Boss Churn. We have also seen a Fairy Churn manufactured by

H. H. Palmer and Company but it is not as common as the Acme Bail and

the Boss Churn. An 1887 advertisement claimed that 150,000 H. H.

Palmer and Company barrel churns were in use in the U. S. and

Canada. The counter weight on some of their barrel butter

churns listed 10 patent dates. All these patents were either

granted to Samuel Palmer or assigned to Henry Palmer. The dates of

these patents were September 2, 1879, June 1, 1880 (reissue of a Sept

4, 1877 patent), February 21, 1882, February 21, 1888, two patents on

December 17, 1889 and four patents on December 31, 1889. The

Palmers were granted additional patents throughout the 1890's.

Also as mentioned above, H. H. Palmer and Company literature claimed

they owned a half interest in John McDermaid's original October 24, 1876

patent. An 1891 H. H. Palmer and Company price sheet listed the

price for a 5 gallon churn like the one pictured here as $8.00.

One sees the great effect that Sears and Wards had on prices as just a

few years later competition from these mail order houses had pushed the

price on the same churn to $3.00 and below.

Even though H. H. Palmer and J. McDermaid shared McDermaid's 1876 patent

they were fierce competitors located in the same little town. In

1892, H. H. Palmer sued J. McDermaid in court. Palmer claimed that

butter churns manufactured by McDermaid were infringing on three of his

patents, one dated February 21, 1888 and two dated December 31,

1889. The court decided in McDermaid's favor, concluding that none

of the Palmer patents covered any novel features. In fact a

patent granted to William Dobson, a third churn

manufacturer also from Rockford, Illinois, on July 5, 1881

covered all the features that H. H. Palmer was calling their

ideas. We see this often in early patents. Often the ideas

described in the patents were not new or unique but manufacturers

still applied for patents to validate or approve their products.

Barrel butter churns are sometimes found with a lever system or foot

pedal that rotates the barrel from a more comfortable standing position

than the hand crank found on the churn shown above (picture). This

lever system we see more often on Canadian barrel churns however William

Dobson of Rockford, Illinois did patent a lever system to rotate a

barrel churn on October 15, 1901. His company, Dobson

Manufacturing Company of Rockford, Illinois, sold a conventional, hand

cranked barrel churn called The Favorite and also sold a lever operated

barrel churn called The Favorite Special.

Barrel butter churns were very common and many companies made them,

especially in Illinois. Sizes up to 150 gallons were available for

use in larger creameries.

Other barrel butter churns include:

The Babcock Favorite and The Jackson manufactured by W. W. Babcock

Co., Bath, New York

The Batcheller Barrel Churn manufactured by H. F. Batcheller & Son,

Rock Falls, Illinois

The Challenge and Diamond Churns manufactured by The Challenge Churn

Manufacturing Co., Paw Paw, Michigan

The Double Lever Churn manufactured by the Aspinwall Manufacturing Co.,

Jackson, Michigan

The Hawthorne listed in 1922 Montgomery Ward catalog, shipped from

northern Illinois

The Magic Churn manufactured by The American Woodenware Manufacturing

Company, Toledo, Ohio

The O. K. Churn manufactured by John S. Carter, Syracuse, New York

Reid's Cedar Churn manufactured by A. H. Reid, Philadelphia,

Pennsylvania

The Standard Barrel Churn manufactured by Standard Churn Company,

Wapakoneta, Ohio (click here to go to the page with wood churns

made by the Standard Churn Co.)

The Stoddard Churn manufactured by Moseley and Stoddard Manufacturing

Co., Poultney, Vermont

The Surprise Churn manufactured by Chapin & Smith, Poultney,

Vermont

Union Barrel Churn manufactured by the Union Manufacturing Company,

Toledo, Ohio

Click here to go to the page with stoneware barrel

butter churns.

Click here to go to the page with metal barrel

butter churns.

The style of butter churn pictured

above is a rectangular churn. The one shown here is

specifically a Whipple's rectangular churn. This one was made by

Cornish, Curtis and Greene Mfg. Co. of Fort Atkinson, Wisconsin.

They were patented January 21, 1868 and July 7, 1885. In the 1868

patent papers Samuel Whipple of Orville, California proposes the

idea of a box shaped butter churn that revolved on trunnions from

diagonal corners. The 1885 patent was granted to David Curtis of

Fort Atkinson, Wisconsin and dealt with improvements in the sealing of

the churn lid and a drain through one of the corner supports. This

patent was assigned in two thirds to Oscar Cornish and Walter

Greene. These men formed Cornish, Curtis and Greene Mfg. Co.,

which was a large manufacturer of dairy items.

The pictured butter churn is the smallest model, a No. 0, that

was 7 gallons. The price for one of these in the

1896 through 1898 Sears catalog was $3.50. They also were

sold in a 10, 12, 20, 26, 40 and 60 gallon size. The 40 and 60

gallon sizes were sold with cranks on both ends of the box and could be

adapted to be driven by an external power source. The last year we

found these listed in the Sears, Roebuck and Company catalog was 1906

and the price for a 7 gallon had dropped to $3.23. The strong

buying power of Sears, Roebuck and Company forced manufacturers to keep

prices in line or risk Sears dropping their product. Montgomery

Ward also advertised rectangular churns in their early catalogs.

The Creamery Package Company which acquired Cornish, Curtis and Greene

Mfg. Co. still offered these churns in their 1912 catalog. By then

the 7 gallon size cost 8 dollars.

There are no paddles inside this churn. Cranking made the box

tumble corner over corner and in the process the cream was churned into

butter. The earliest churns used a lid that wedged tight with a

slight rotation (picture). This design was also shown

in the patent papers. Later churns, like the one pictured

here, utilized the sealing mechanisms found on many barrel butter

churns. We suspect that these lids formed a tighter seal and as

the patents ran out they could be used on this churn. The

stenciling on the churn boasts of first place premiums won at state

fairs in Wisconsin, Michigan, Minnesota, Nebraska, Illinois, St. Louis

and Iowa. The stenciling also tells of a first place premium and

medal from the World's Industrial and Cotton Centennial Exposition in

New Orleans, a gold medal from the Grand Union Dairy Fair in Milwaukee

in 1882 as well as a sweepstakes gold medal awarded in St. Louis in

1883.

Although this butter churn design was patented in 1868 and 1885 the

design was still in use in 1939. Click here for a picture of a revolving churn

installed in the Oakland plant of the Challenge Cream and Butter

Association in that year. At the time this was the largest butter

churn in America. It could churn 660 gallons of cream into 2580

pounds of butter in 30 to 45 minutes. The castings were aluminum

and weighed 1500 pounds. At the time they were some of the largest

pieces of aluminum ever cast. This butter churn was manufactured

by the Jensen Machinery Company of Oakland, California. The churn

and the process to use it was patented by Clyde Mitchel of El Monte,

California and Elbert Wetmore of Alhambra, California by way of two

patents issued on May 14, 1940. They assigned both patents to the

Challenge Cream and Butter Association.

The drawing above is taken from

an 1893 advertisement for the Diamond Balance churn. It was sold

by the Diamond Balance Churn Company of Balston Spa, New York. The

inventors of this churn were Matthew Hoyt and Hugh Murray, also of

Balston Spa. They were granted a patent for this churn on May 28,

1889. One problem with tumbling churns such as barrel churns or

the Whipple churn was that they tended to be jerky in their

motion. As the container rotated the cream would fall to the low

end of the container and then have to be lifted back up. This

meant that the churn tended to crank easy and then hard as it went

through one revolution. In the Diamond Balance churn there was a

center divider that basically divided the square box into two

smaller triangular compartments. Half the cream was always on the

opposite side of the centerline to balance the weight and give the churn

a smooth motion. They were advertised as being available in hand

cranked and power versions.

Displayed above is a R. W. Fenner butter churn. Its

inventor was Rufus Fenner. This also was a revolving style of

butter churn like a barrel churn or box churn. However it had a

six sided or hexagonal container. In a barrel churn the cream

would fall twice every revolution, in a box churn it would fall four

times but in this churn the cream would fall 6 times resulting in a more

even, smoother motion. Advertisements from 1893 listed R. W.

Fenner of South Stockton, New York as the manufacturer and sizes from

one cow up to 500 gallons were advertised. This butter churn was

also advertised to not only churn the butter but also work out the

buttermilk, eliminating the need for a separate butter worker.

This is one churn that we believe was never patented.

At some point Fredrickson Bros. of Cassadaga, New York and later

Jamestown, New York purchased the rights

to manufacture this butter churn, as many will be found with

their name. We have seen advertisements as late as 1923 for this

butter churn. They advertised sizes from 6 gallons up to 500

gallons. The larger sizes had a pulley to be driven by a motor

and had two covers to remove the butter.

When we first saw this rocking

device it was described as a washing machine but we thought maybe it was

a butter churn. None of the stenciling gave any indication as to

the intended function. It was called The Perfect and was made by

T. G. Hutcheson of San Jose, California. It was stenciled with an

October 29, 1889 patent date. This patent was issued to Enos

Churchill of Tulare, California and was partially assigned to William

Morrow of San Luis Obispo, California. The title of the patent is

for a washing machine however when one reads the specifications of the

patent it is claimed to wash clothes and churn butter. We are not

sure of the effect one job had on the other. Neither buttery

clothes nor sudsy butter sounds too good. Churchill claimed that

as the unit was rocked back and forth the cream would move towards the

up swept ends, in the process the trapped air would be compressed and

then forcibly driven back through the cream breaking up the

fat globules. The patent said that the churn could be mounted on

rockers like the one above or pivoted on spring brackets. The

sides of the churn are wood while the top, ends and bottom with all the

curves are tin.

Thanks to the Yolo county Historical Museum in

Woodland, California for letting us picture this churn.

The churn pictured above is a rocker

butter churn. The cream box is mounted on rockers just like a

rocking chair. We have seen them with wood rockers like this churn

or with cast iron rockers. Often these churns would have some

type of fixed dasher in the center of the box. Not only was the

cream churned as it hit the end of the box but it had to also pass

through the fixed dasher in the center of the box as it moved from

end to end. These churns were easy to build and many people just

built one of their own design. That probably explains why one

comes across unique rocker butter churns.

George Bell of Sumner, Michigan was granted a patent on April 17, 1877

for a churn of this style. His design also included a false

bottom of sheet metal. The cream was above the sheet metal

bottom and water could be added to the space between the sheet metal and

the bottom of the wood box. By adjusting the temperature of the

water one could improve the ability of the cream to form butter.

We also came a cross a 1904 advertisement for the Rocker Churn, very

similar to the one shown above. They were made by the Rocker Churn

Manufacturing Company for Forsyth, Georgia. The company

advertised eight sizes from 8 to 60 gallons. The thrust of their

advertising was simplicity. Definitely this design needed little

maintenance or adjustment and was very easy to keep clean. |

|